1. Why CNC Machining Quotes Vary So Much

If you have ever sent the same CNC machining RFQ to five suppliers and received prices that differ by 2×, 5×, or even more, you are not alone. This price spread is one of the most confusing—and frustrating—parts of sourcing CNC-machined parts. The key reason is simple: CNC machining quotes are not purely price calculations; they are risk evaluations. Every supplier reads your drawings and RFQ, identifies uncertainties, and then decides how much risk they are willing to accept. The more risk they perceive, the higher the price—or the longer the lead time. Unlike standardized commodities, CNC machining involves:- Custom geometry

- Variable tolerances

- Material availability differences

- Different machine tools and workflows

- Different quality systems and inspection depth

2. What Actually Goes Into a CNC Machining Quote

To understand why prices vary, it helps to break down what a CNC machining quote really includes. A typical quote is built from several internal cost blocks:- Material cost: raw stock price, yield, scrap risk

- Programming: CAM time, setup planning

- Setup: fixturing, tool changes, probing

- Machine time: cutting time, tool wear

- Labor: operator time, supervision

- Inspection: measurement time, CMM usage

- Overhead: quality system, utilities, depreciation

- Risk buffer: uncertainty premium

3. Hidden Assumptions That Change Prices

The biggest reason CNC machining quotes vary is hidden assumptions. If your RFQ does not explicitly define a requirement, each supplier fills in the gap differently. Common assumption gaps include:- Tolerances: “Standard tolerance” interpreted loosely or strictly

- Surface finish: visual vs functional Ra requirements

- Inspection scope: spot check vs full dimensional report

- Material equivalency: exact grade vs local substitute

- Packaging: bulk packing vs protective separation

4. Tolerances: The #1 Cost Multiplier

Tolerances are often the single biggest driver of price variation. Tight tolerances increase cost in multiple ways:- Slower cutting speeds

- More stable fixturing

- Additional finishing passes

- Higher scrap risk

- More inspection time

5. Material Choice and Sourcing Differences

Material cost is not just about the alloy name—it includes availability, yield, and supplier relationships. Examples:- One shop buys Aluminum 6061-T6 locally at stable prices.

- Another shop imports the same grade with longer lead time.

- One supplier allows 6082-T6 as an equivalent; another does not.

6. Manufacturing Strategy & Machine Capability

Suppliers do not all machine parts the same way. For example:- A 5-axis shop may machine the part in one setup.

- A 3-axis shop may require multiple setups and fixtures.

- One shop may use soft jaws; another builds a custom fixture.

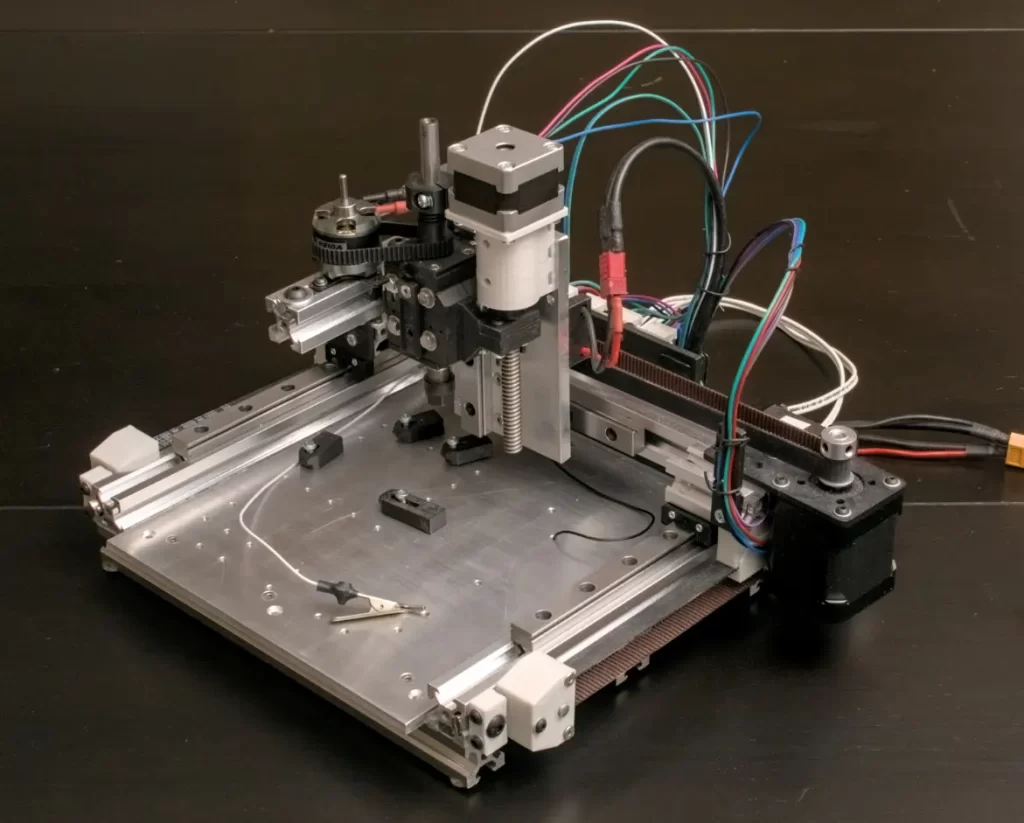

How CNC Machines Used by Different Suppliers Affect Quotation

One often overlooked reason why CNC machining quotes vary so much is the type of machines and equipment used by different suppliers. Even when quoting the same drawing, suppliers may rely on very different machining setups, which directly influence cost structure, risk level, and pricing strategy. It is important to understand that machine capability does not automatically mean better quality. However, it strongly affects setup strategy, cycle time, inspection workload, and tolerance control—all of which are reflected in the final quotation.3-Axis vs 4/5-Axis CNC Machines

One of the most common differences between CNC machining suppliers lies in the number of machine axes available.- 3-axis CNC machines are widely used and cost-efficient for simple geometries. However, complex parts often require multiple setups, increasing setup time, cumulative tolerance error, and inspection effort.

- 4-axis and 5-axis CNC machines can machine multiple faces in a single or reduced number of setups. This often lowers total setup cost, improves geometric consistency, and reduces manufacturing risk.

Machine Age, Automation, and Process Stability

Another major difference comes from the generation of machines and level of automation used by suppliers:- Older machines often rely on manual setup, manual probing, and conservative cutting parameters.

- Modern CNC machines typically include automatic probing, tool length measurement, and adaptive control, allowing faster setup and more stable machining.

How Machine Capability Translates Into Quote Differences

| Machine Capability | Typical Supplier Setup | Impact on Quotation |

|---|---|---|

| 3-Axis CNC | Multiple setups, manual fixturing | Lower hourly rate, higher setup and risk cost |

| 4/5-Axis CNC | Single or reduced setups | Higher hourly rate, lower total manufacturing cost |

| Older-generation machines | Manual probing, slower feeds | Longer cycle time, conservative pricing |

| Modern CNC with automation | Automatic probing and stable processes | Faster setup, more predictable pricing |

7. Inspection, Quality, and Documentation Costs

Inspection is frequently underestimated by buyers and inconsistently interpreted by suppliers. Inspection-related cost drivers include:- Manual vs CMM inspection

- Number of dimensions measured

- First Article Inspection (FAI)

- Traceability and documentation

- Customer-specific quality systems

8. Lead Time, Priority, and Capacity Effects

Lead time is another major source of variation. Short lead times often mean:- Overtime labor

- Queue jumping

- Rescheduling other jobs

9. How to Compare CNC Machining Quotes Correctly

To compare quotes fairly, you must normalize them. Ask each supplier to confirm:- Material grade and source

- General and critical tolerances assumed

- Surface finish included

- Inspection scope and documentation

- Lead time and delivery terms

- Exclusions or assumptions

10. Common Buyer Mistakes When Comparing Quotes

- Choosing the lowest price without checking assumptions

- Ignoring inspection and quality scope

- Comparing different lead times as if they were equal

- Overlooking material substitutions

- Failing to consider long-term production pricing

11. Quote Comparison Checklist

- [ ] Same material grade and condition

- [ ] Same tolerance assumptions

- [ ] Same surface finish and post-processing

- [ ] Same inspection and documentation

- [ ] Same lead time and Incoterms

- [ ] Same quantity and future volume assumptions