Why Accurate CNC Quotes Depend on Information Quality

From a buyer’s perspective, a CNC machining quotation often appears to be a simple calculation: raw material cost plus machining time, with some margin added. In reality, CNC machining suppliers approach quoting very differently.

For suppliers, quoting is not just a pricing exercise—it is a risk assessment process. Before committing to a price, lead time, and delivery promise, a supplier must evaluate whether the part can be manufactured reliably within their existing capabilities, capacity, and quality system.

When information is incomplete, suppliers face uncertainty in areas such as:

- Machining strategy and number of setups required

- Tolerance feasibility and inspection workload

- Material availability and substitution risk

- Scrap probability and rework exposure

- Delivery risk under the requested timeline

To protect themselves, suppliers respond to uncertainty in predictable ways: they delay quoting to ask questions, they add risk buffers to the price, or they quote conservatively with longer lead times. Understanding what information suppliers actually need is the fastest way to receive accurate, competitive, and comparable CNC machining quotes.

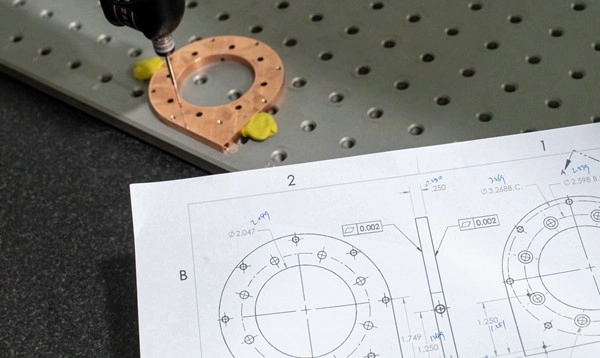

1. Clear and Complete Drawings (2D + 3D)

Drawings are the foundation of every CNC machining quote. Without clear drawings, no supplier can confidently evaluate manufacturability, cost, or risk.

Suppliers typically expect:

- 2D drawings (PDF): fully dimensioned, with tolerances, notes, threads, and surface requirements

- 3D models (STEP or IGES): to support CAM programming and reduce interpretation errors

From a supplier’s perspective, the 2D drawing is the legal and technical reference, while the 3D model is a productivity tool. Missing either one slows down quoting and increases uncertainty.

Equally important is revision control. Suppliers need to know that the files they are quoting against are final and consistent. Drawings without revision identifiers or with mismatched 2D and 3D files introduce risk that suppliers must price in.

When drawings are unclear or incomplete, suppliers must guess intent—and guessing always increases cost.

2. Defined Tolerances and Functional Requirements

Tolerances are one of the most critical inputs for CNC machining quotes. They directly affect machining speed, setup complexity, inspection effort, and scrap risk.

Suppliers need clarity on:

- General tolerance standard (for example, ISO 2768)

- Critical dimensions with tighter requirements

- GD&T requirements such as flatness, position, or concentricity

- Fit requirements (press-fit, slip-fit, bearing fits, thread classes)

When tolerances are not defined, suppliers must assume worst-case scenarios. Some suppliers may assume tight tolerances across the entire part, while others may assume relaxed standards. This difference alone can lead to large price variations between quotes.

Clear tolerance definition allows suppliers to design efficient machining and inspection strategies instead of pricing defensively.

3. Exact Material Grade and Condition

Material specification is far more than naming a general category such as “aluminum” or “steel.” CNC machining suppliers need to know the exact material grade and condition to assess cost, machinability, tooling, and lead time.

Critical material information includes:

- Material grade (e.g., Aluminum 6061-T6, Stainless Steel 304, 4140)

- Material condition or temper (T6, annealed, hardened)

- Whether equivalent grades are acceptable

Material sourcing varies widely by region and supplier. Some shops have strong local supply chains for specific grades, while others may face longer procurement times or higher costs. Without clarity on material requirements, suppliers cannot quote accurately.

Allowing material equivalents—when functionally acceptable—can significantly reduce cost and lead time, but this must be explicitly stated in the RFQ.

4. Quantity Structure and Volume Expectations

Quantity is not just a number—it defines the entire pricing logic for CNC machining.

Suppliers need to understand:

- Prototype quantity

- Initial batch size

- Potential production or annual volume

A quote for five prototype parts will be structured very differently from a quote for 500 production parts. Setup cost, programming effort, inspection strategy, and even machine selection change with volume.

When buyers provide only a single quantity without context, suppliers may quote conservatively. Providing realistic volume expectations allows suppliers to optimize pricing and capacity planning.

5. Surface Finish and Post-Processing Requirements

Surface finish requirements strongly influence machining time and downstream processes. Suppliers need explicit information on both functional and cosmetic expectations.

This includes:

- Surface roughness targets (Ra values)

- Cosmetic requirements or visual standards

- Post-processing such as anodizing, plating, coating, or heat treatment

- Areas where finish requirements are critical

Without this information, suppliers may assume minimal finishing or, conversely, assume demanding cosmetic standards. Either assumption can distort pricing.

Clear surface finish definitions help suppliers align machining strategy, tooling, and secondary operations accurately.

6. Inspection and Quality Documentation Scope

Inspection is one of the most underestimated cost drivers in CNC machining.

Suppliers need to know:

- Whether material certificates are required

- Which dimensions must be measured and reported

- Whether First Article Inspection (FAI) is required

- Whether CMM inspection is needed

- Any customer-specific quality standards

Inspection effort can range from simple spot checks to full dimensional reports with traceability. These differences have a major impact on quote price and lead time.

When inspection scope is unclear, suppliers either underquote and risk disputes, or overquote to protect themselves.

7. Delivery Terms, Lead Time, and Logistics

Accurate quotes also depend on clear delivery expectations.

Suppliers need information on:

- Delivery location

- Incoterms (EXW, FOB, CIF, DDP, etc.)

- Target lead time

- Packaging requirements

Short lead times may require overtime, priority scheduling, or expedited material procurement. These factors must be reflected in the quote.

When delivery terms are undefined, suppliers cannot align pricing with logistics reality.

8. Risk Expectations and Communication Style

Finally, CNC machining suppliers need to understand the buyer’s tolerance for risk and flexibility.

Suppliers benefit from knowing:

- Whether design changes are acceptable for manufacturability

- Whether cost optimization is prioritized over speed

- How issues or deviations should be communicated

Buyers who invite manufacturability feedback often receive better quotes, because suppliers can suggest process improvements rather than pricing rigidly against imperfect designs.

Conclusion

Accurate CNC machining quotes are not driven by price formulas—they are driven by information quality. Suppliers need a complete technical and commercial picture to assess manufacturability, cost, and risk.

By providing clear drawings, defined tolerances, precise material specifications, realistic quantities, explicit inspection requirements, and clear delivery terms, buyers enable suppliers to quote with confidence rather than caution.

In CNC machining, clarity is not just helpful—it is the foundation of accurate pricing, reliable delivery, and successful long-term supplier relationships.