What Does CNC Mean?

CNC stands for Computer Numerical Control. It refers to a manufacturing method in which the movement and operation of machine tools are controlled by a computer program rather than manual operation. Before CNC technology became widespread, machining was performed manually. Skilled machinists controlled handwheels, levers, and dials to move cutting tools and workpieces. While effective, manual machining relied heavily on operator skill and was limited in speed, consistency, and complexity. CNC technology transformed machining by allowing machines to follow precise digital instructions. Once a program is created and loaded, the CNC machine executes the same operations repeatedly with minimal variation, regardless of operator fatigue or production volume.What Is a CNC Machine?

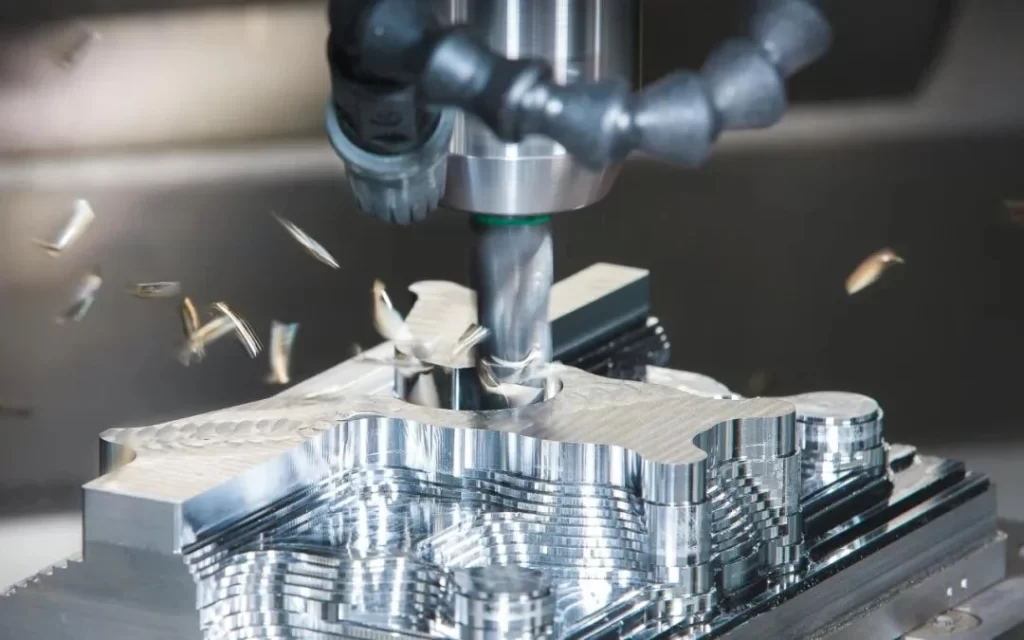

A CNC machine is a piece of equipment that uses computer software to control the motion of cutting tools and workpieces. These machines interpret programmed instructions—typically written in G-code—to perform machining operations such as milling, turning, drilling, boring, and cutting. In simple terms, a CNC machine converts a digital design into a physical part by removing material from a workpiece with controlled, automated movements. CNC machines are used across a wide range of industries because they offer:- High dimensional accuracy

- Excellent repeatability

- Consistent quality

- Reduced human error

- Efficient production of complex geometries

How Does a CNC Machine Work?

Although CNC machines come in many forms, they all follow the same basic workflow.1. Digital Design

The process begins with a digital part design, usually created using CAD (Computer-Aided Design) software. The CAD model defines the shape, dimensions, and features of the part.2. Toolpath Programming

The CAD file is then converted into machining instructions using CAM (Computer-Aided Manufacturing) software. CAM software generates toolpaths that specify:- Cutting tool movements

- Feed rates and spindle speeds

- Depth of cuts

- Tool changes

3. Machine Setup

Before machining begins, the operator sets up the CNC machine by:- Installing cutting tools

- Securing the workpiece

- Setting reference points (work offsets)

- Loading the CNC program

4. Automated Machining

Once started, the CNC machine follows the programmed instructions precisely. Motors drive the machine axes, moving tools or workpieces along predefined paths to remove material.5. Inspection and Finishing

After machining, the part may be inspected for dimensional accuracy and surface quality. Additional finishing processes may be applied if required.Main Types of CNC Machines

CNC machines are classified based on the type of machining operation they perform. Below are the most common types used in manufacturing.CNC Milling Machines

CNC milling machines use rotating cutting tools to remove material from a stationary workpiece. They are highly versatile and capable of producing complex shapes, pockets, slots, and contours. Milling machines may be configured as:- 3-axis CNC mills

- 4-axis CNC mills

- 5-axis CNC mills

CNC Lathes and Turning Centers

CNC lathes rotate the workpiece while a stationary cutting tool removes material. This process is ideal for cylindrical or rotational parts such as shafts, bushings, and fittings. Modern CNC turning centers often include live tooling, allowing milling and drilling operations to be performed in a single setup.CNC Drilling Machines

CNC drilling machines are designed primarily for creating holes with high accuracy and consistency. They are commonly used in mass production environments.CNC Grinding Machines

CNC grinding machines use abrasive wheels to achieve very fine surface finishes and tight tolerances. They are often used for finishing hardened components.CNC Laser, Plasma, and Waterjet Machines

These CNC machines use non-contact cutting methods:- Laser cutting: uses focused laser beams

- Plasma cutting: uses ionized gas

- Waterjet cutting: uses high-pressure water, sometimes with abrasives

Common Materials Machined by CNC Machines

CNC machines can process a wide variety of materials, depending on machine capability and tooling. Common materials include:- Aluminum alloys

- Steel and stainless steel

- Brass and copper

- Titanium and superalloys

- Engineering plastics (POM, ABS, PTFE, Nylon)

- Composites

Advantages of CNC Machines

CNC machines offer several key advantages over manual machining.- High precision: CNC machines can achieve tight tolerances consistently.

- Repeatability: Identical parts can be produced with minimal variation.

- Efficiency: Automated machining reduces cycle time and labor.

- Complex geometry: CNC allows shapes that are difficult or impossible manually.

- Reduced human error: Programs eliminate variability from manual control.

Limitations of CNC Machines

Despite their advantages, CNC machines also have limitations.- High initial investment cost

- Programming and setup expertise required

- Less economical for very low-volume simple parts

- Maintenance and calibration requirements

Where Are CNC Machines Used?

CNC machines are used in almost every modern manufacturing industry.- Aerospace: structural components, engine parts

- Automotive: engine blocks, transmission components

- Medical: implants, surgical instruments

- Electronics: housings, connectors

- Industrial equipment: gears, fixtures, tooling

CNC Machine vs Manual Machine

The difference between CNC and manual machines lies in control and consistency. Manual machines depend on operator skill, while CNC machines rely on programmed instructions. CNC machines are better suited for:- Complex parts

- Tight tolerances

- Medium to high production volumes

- Consistent quality requirements